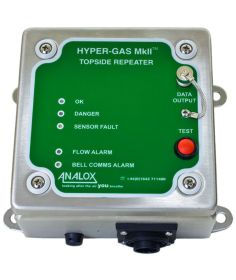

Analox Hyper-Gas MkII Hydrocarbon Bell Monitor

The Analox Hyper-Gas MkII Hydrocarbon Bell Monitor is designed to detect and warn divers of potentially fatal anesthetic levels of hydrocarbons in the diving bell.

Restrictions / Notifications

- Non-Returnable/Non-Cancelable

This item cannot be canceled or returned once an order has been placed.

Features

Includes

Sensor Specifications

|

The Analox Hyper-Gas MkII™ Hydrocarbon Bell Monitor is designed to detect and warn divers of potentially fatal anesthetic levels of hydrocarbons in the diving bell. Where divers are working on dirty sites, there is the likelihood for contamination of the bell atmosphere from vaporization of contaminants carried on dive suits and umbilical lines even when divers are wearing additional safety dive suits.

In the presence of anesthetic levels of volatiles, divers can suffer the effects within a few breaths. Even before unconsciousness, the ability to react normally becomes impaired. The effects caused by sub anesthetic levels can be compared with the pattern of behavior caused by alcohol consumption.

The following effects have been detailed by Fang et al. (1996):

- 33% of the anesthetic level of toluene leads to hyperactivity.

- 13% of the anesthetic level of xylene causes tremors which could impair purposeful actions.

- 44% of the anesthetic level of benzene causes uncontrolled jerking of limbs.

- 52% of the anesthetic level of cyclo-hexane causes convulsions.

The Hyper-Gas MkII™ system has been designed to operate to depths up to 60 Bar A. It uses a unique hyperbaric hydrocarbon sensor based on highly respected Analox infra-red technology. The sensor is sensitive to a range of hydrocarbons and is able to detect all those commonly given off by the vaporization of crude oil or condensate.

Automatic correction of pressure and temperature effects ensures the analyzer will offer optimum performance in this difficult environment.

The gas alarm level is preset to 10% of the anesthetic dose of vaporized hydrocarbons that could be present in the diving bell. The sensor gives an additive response to the range of hydrocarbons normally present, not one individual compound. For diving in areas where contamination is known to be from 1 or 2 compounds, an alternative alarm set point could be calculated by Analox.

The sensor needs to be mounted within the diving bell, rather than relying on an umbilical fed analyzer because anesthesia, or the effects of sub anesthetic levels can occur within a few breaths, i.e. a few seconds. By analyzing for hydrocarbons at the surface, it is likely that the effects would occur before an alarm is raised. A rapid response is crucial. The Hyper-Gas MkII™ has been designed with an internal sample pump to ensure a fast response to hydrocarbons.

The Hyper-Gas MkII™ system is fitted with a factory set data logging facility. This logs and measures the levels of hydrocarbons, the depth and the corresponding data and time. Once the data logging capacity is exceeded, the Hyper-Gas MkII™ will automatically overwrite the oldest data. Data can be downloaded via the topside repeater or bell monitor onto a PC using the data communications cable and the data log retrieval program.

Note: We strongly recommend that for every Bell Monitor purchased that customers purchase a spare Replacement Manifold too.

FAQ's

The shelf life of the manifold is 18 months.

Amron International Customer Service

We respond to most inquiries within 24 hours, Monday – Friday, excluding holidays.Phone

Toll-Free: (877) 462-6700Local & International: (760) 208-6500

Fax: (760) 599-3857

Hours of Operation

Customer ServiceMonday - Friday, 8am – 5pm Pacific Time Zone

Warehouse/Will Call Orders

Monday – Friday, 9am – 3:30pm Pacific Time Zone